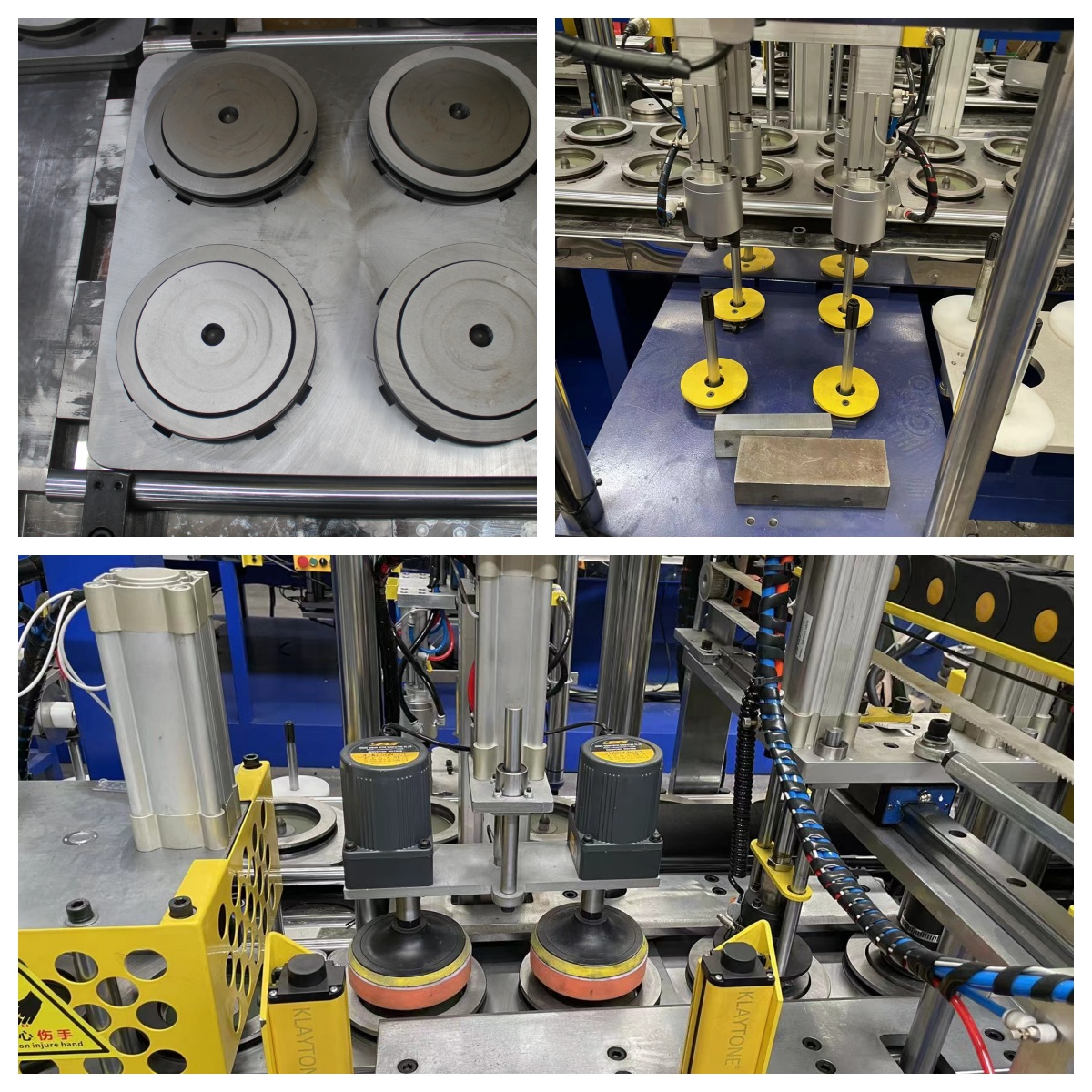

1.Used for molding of fiber-reinforced resin grinding wheel.

2.The application of this unit for completion of material paving, net pressing, mold unloading, compacting, transformation of covers and other major molding process greatly improves its balance performance and stable quality of the grinding wheel embryo and reduces the labor intensity effectively.

3. By using PLC primary graduation for rotation and precision graduation for positioning device respectively, the large turntable can be positioned precisely.

4. Key component parts, such as speed reducer, hydraulic pressure, pneumatic components and electric control components etc., either imported or produced by joint venture enterprises and with introduced technology improves the reliability of devices and diminishes the failure rate effectively.

5. With upper and lower indenter and slide mold heating devices, it can make both cold & hot pressing products and is suitable for automatic molding of a variety of grinding wheels.

6. Same-diameter and different-thickness grinding wheels can be produced with the same set of mold.

7. The mold is easy to be manufactured for its identical structure to the ordinary manual molds.

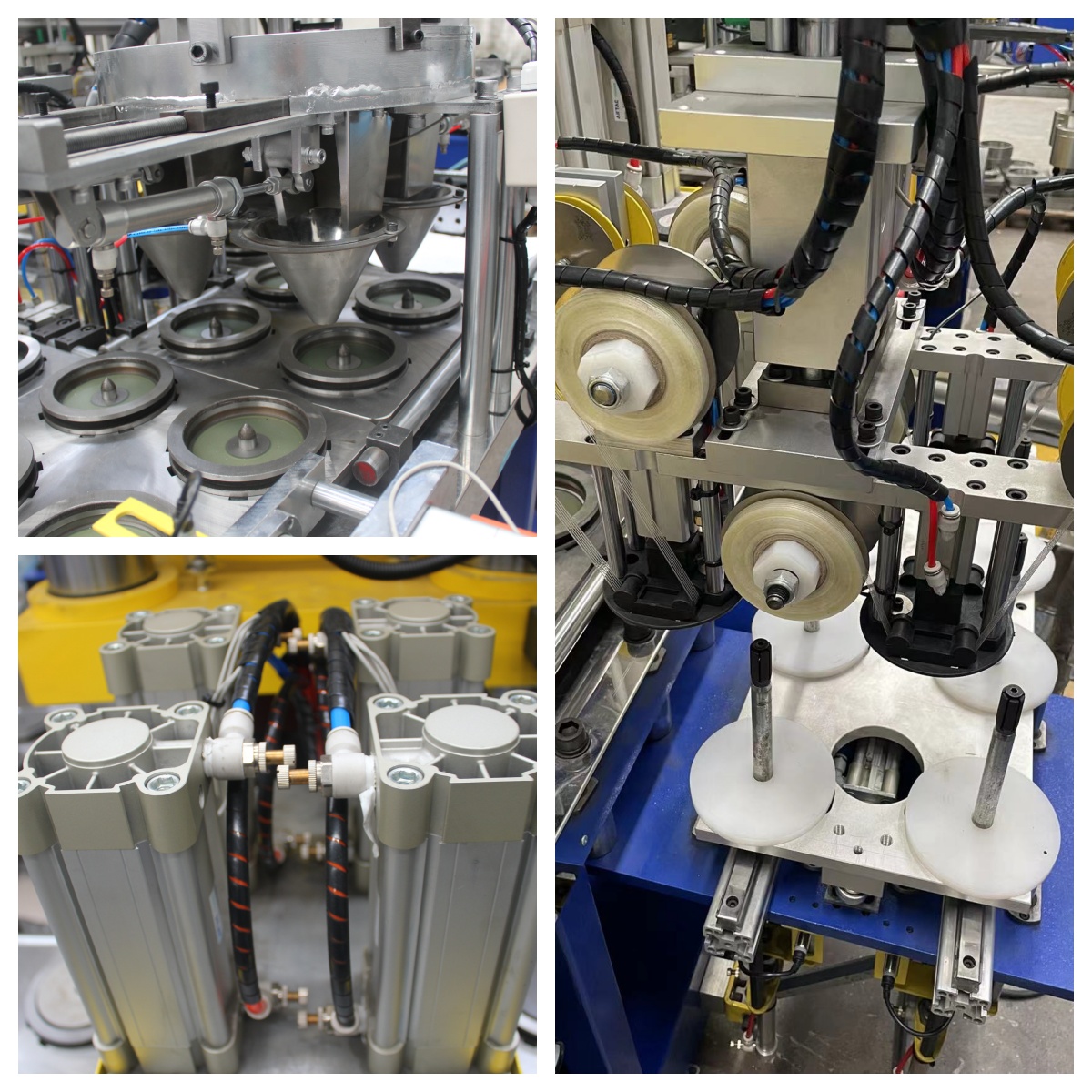

8. The frequency conversion motor drives the pull rod, elevating the scraper slightly, therefore, the scraping process is stable, reliable and free from pressure fluctuations.

9. According to user’s request, we can produce all kinds of technical parameters and model machine.

10. With preloading and pre-discharging automatic device for transportation of cover, the cymbals wheel can finish the convex compression of trademarks, black paper and net etc.

11. Replacing the mold can easily achieve the change of product varieties and specifications.

Cutting disc D105-125mm | |||

Product type | Single head machine | Single head machine | Double head machine |

1 and 2 net cutting disc | grinding disc | 1 and 2 net cutting disc | |

1 & 2 net cutting disc | |||

Working station: | 30 | 42 | 52 |

Molds amount: | 28 | 40 | 50 |

Hydraulic pressure: | 125T | 125T | 150T |

Machine work mode: | Air cylinder circulate push | Air cylinder circulate push | Air cylinder circulate push |

Control model: | PLC | PLC | PLC |

8-hour products: | 5000-5500PCS | 5000-5500PS | 10000-11000PCS |

Total power: | 9-14KW | 10-15KW | 10-15KW |

Automatic function: | Automatic material paving X2 | Automatic material paving X3 | Automatic material paing X4 |

Transportation covers X1 | Transportation covers X2 | Transportation coves X2 | |

Pre-compaction covers | Pre-compaction covers | ||

Online Chat

YouTube