Material mixing, which is an important procedure in mould production, refers to a process in which external forces that change both in speed and direction move mould materials (including grinding material, binder and accessories) to evenly mix the grinding material and other materials and to evenly spread the binder on the surface of the grinding material. The more even the binder is spread on the surface of the grinding material, the more likely a high quality mould with even texture will be produced.

Countercurrent double-pot mixer is specially designed for the mixing of shaping materials of moulds with porcelain/resin binder.

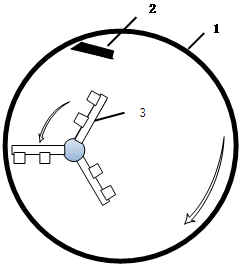

Working Principle of Countercurrent Mixing Pot

1. Material Pot 2. Scratch Board 3. Star-shaped

1. The mixing knife and the material pot are installed eccentrically and rotate reversely; the design of the pot is unique and the design of the motion path is reasonable, thus guaranteeing the material-mixing to be effective and even;

2. The supporting point for the rolling of the material pot is close to the opening of the pot, thus the discharging height is higher and the feeding height is lower, thus making operation easier and reducing labor intensity. As the discharging opening is high, there is sufficient space under the pot for the trolley or vibrating sieve, thus facilitating transfer of the materials;

3. Complete discharging and easy cleaning.

Automatic Hydraulic Countercurrent Mixer | ||

Equipment include | 100kg full automatic mixer | 1/set |

100kg full automatic mixer | 1/set | |

Vibrating sieve | 1/set | |

Automatic controller box | 1/set | |

Hydraulic pumping station | 1/set | |

Online Chat

YouTube